Heat Treatment

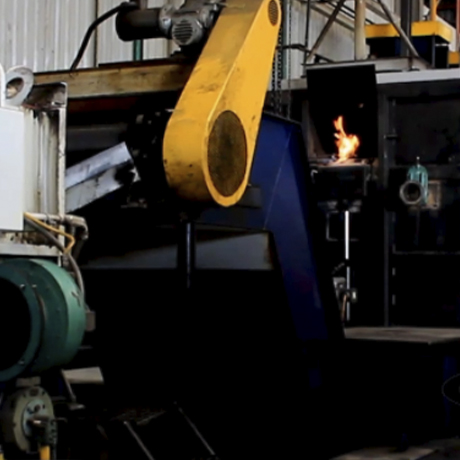

Heat treatment is a method or process used to alter the physical, and sometimes chemical, properties of a material. Heat treat involves the use of heating, normally to extreme temperatures to improve the mechanical properties of the material, such as hardening, tenacity or softening of a material. Crio is a company fully dedicated to offer quality heat treat in the most modern equipment with the a strict quality control.

Oil Quench and Temper

Carburizing

Tempering

Annealing

Normalizing

Stress Relief

Press Quench.

Cryogenic

FNC

Austemper *

Aluminum*

Etc.

OUR SERVICES

Carburizing

This Process is done under a protective endotermic atmosphere adding enrichment gas contolling the desired carbon potential sufficient and capable of getting the desired case depth of carbon in a given time of the process. Quenched in Oil to get the hardness on the core of the piece, then temperig to elimiate tensions originated during the quench, obtaining a surface with the resistance, endurance required and ductil core.

Carburizing: Spread coal in the iron-based alloy surface heating up austenitizing in the presence of carbon-rich atmosphere. This treatment followed by a hard right stamp the metal surface.

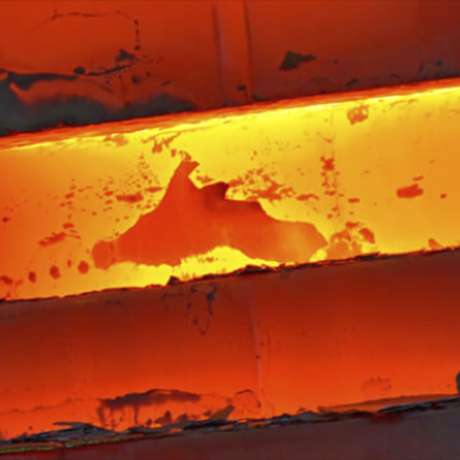

Oil Quench

Oil quench is done on different types of furnaces depending on the geometry of the load, the process temperature is from 815 – 870 ºC under a protective endothermic atmosphere with a carbon potential which matches the type of steel. After heating the load for a given time it is oil quenched to get the desired hardness followed by a tempering process to eliminate tension originated during the quench.

Tempering

Tempering is a thermal heat treatment which follows the quenching of steel. The purpose is to reduce the internal tensions of the piece originated by the quenching or by the distortion. It improves the mechanical characteristics, by reducing the fragility and slightly the strength. The process temperature is between 165ºC – 650 ºC.

Carbonitriding

The process of Carbonitriding is done under an endothermic atmosphere with an addition of ammonia and an enrichment gas, maintaining the temperature over the Ac1 for a given time to obtain the desired case depth. Quenching in oil to obtain a hard surface with high resistance and a tempering is then used to eliminate the tensions originated during the quench.

Annealing

Annealing consists on heating and holding to a suitable temperature, followed by a controlled cooling cycle of considerable time at a suitable rate. Used primarily to soften metallic materials, but also to simultaneously produce desired changes in other properties or in microstructure. The purpose of such changes may be, but is not confined to: improvement of machinability, facilitation of cold work, improvement of mechanical or electrical properties, and/or increase in stability of dimensions.

Normalizing

This process is typically confined to hardenable steel. It is used to refine grains which have been deformed through cold work, and can improve ductility and toughness of the steel. It involves heating the steel to just above its upper critical point. It is soaked for a short period then allowed to cool in air. Small grains are formed which give a much harder and tougher metal with normal tensile strength and not the maximum ductility achieved by annealing. Normalizing improves machinability of a component and provides dimensional stability if subjected to further heat treatment processes.

Stress Relief

It is recommended for pieces that have been welded, steel melted pieces, etc. This process is done at a temperature below 723ºC, usually 650ºC.

Press Quench

A quench in which hot dies are pressed and aligned with a part before the quenching process begins. Then the part is placed in contact with a quenching medium in a controlled manner. This process avoids parts distortion.